Two modern laboratories for thermal, hydraulics, materials inspection and reliability testing and validation

Testing has been the focus of COOLTECH since the beginning. Every year we invest in expanding our testing equipment and facility to allow our engineers to be able to reproduce real and extreme conditions. Qualification testing is a very important step of the development process, creating the basis to avoid issue in the field.

Our test lab performs confidence tests, qualification tests, reliability and HALT lifetime tests, metallurgical and dimensional inspections.

Our test capabilities include:

- Temperature controlled room of 12 sqm where lifetime tests are performed.

- Temperature and humidity controlled room of 14 sqm where functional tests are performed. We can simulate ambient temperatures from room temperature to 60°C and humidity up to 95%.

- Votch 340L temperature and humidity chamber, to simulate environmental temperature from -40°C to +180°C, with humidity control.

- Pressure cycling equipment for fatigue testing of components or assemblies.

- Heat load simulator for thermal testing of cooling units up to 70 kW

- Heat load simulator for thermal testing of cold plates up to 40 kW

- Set of equipment to prepare samples for metallurgical inspection.

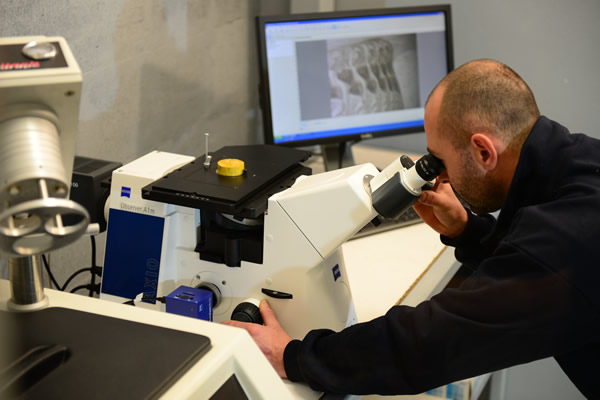

- ZEISS 1000x microscope for metallurgical analisys of welded or brazed joints

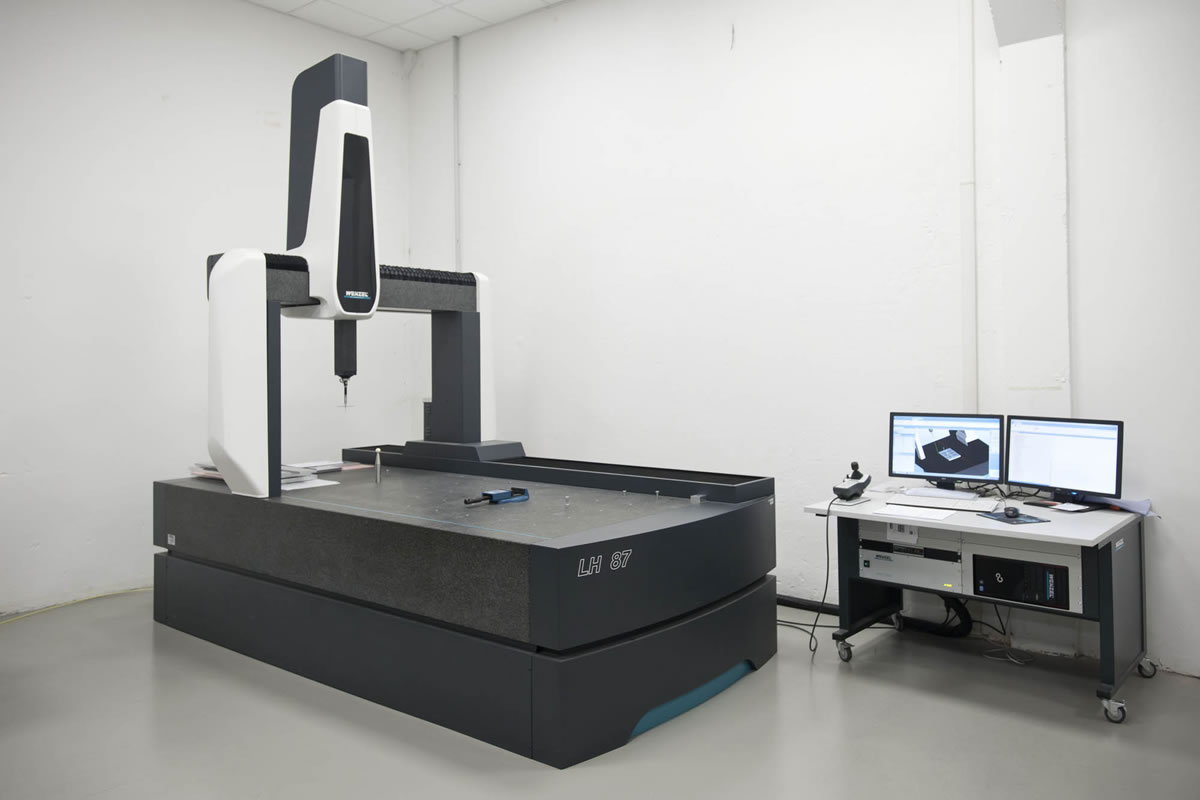

- WENZEL 3D CMM (coordinates measurement machine) with measuring area of 2000x800x700h mm.

- Many temperature, pressure and flow sensors used in our test benches.