CNC welding of linear joints.

No material addition, no flux and completely

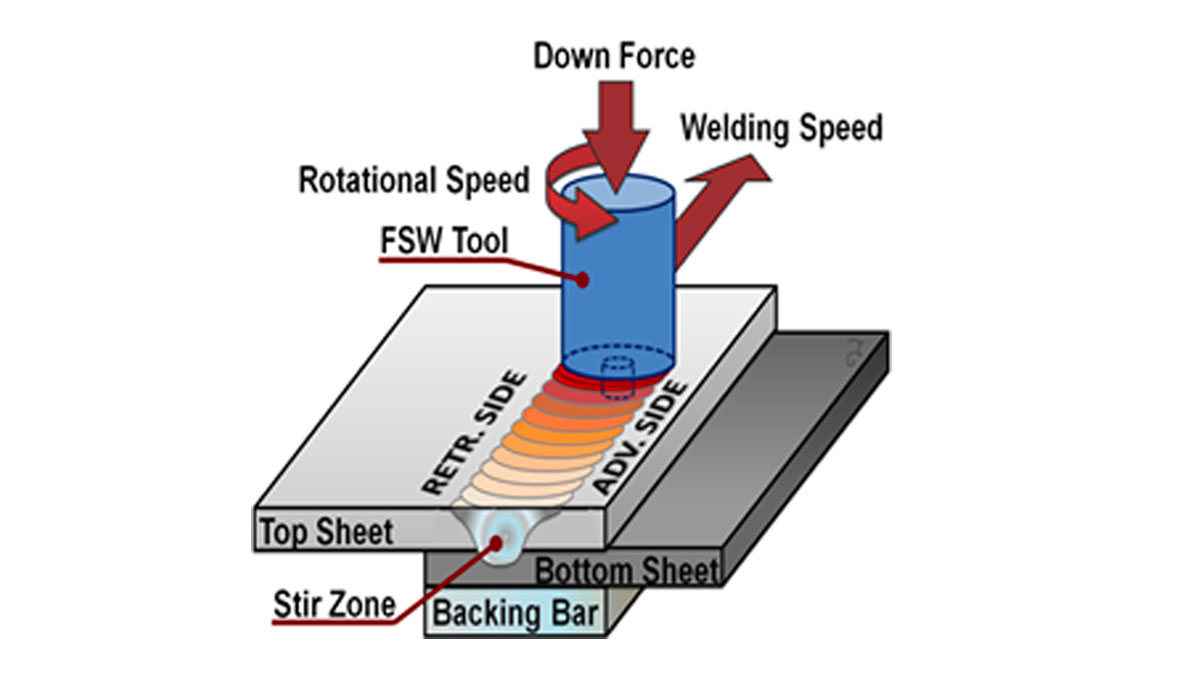

Friction Stir Welding is a completely automated, CNC-driven process which is used to weld two parts together by mean of a plastic deformation process.

There is no melting, but just a plastic deformation providing high quality, leak-tight joints.

Contrary to vacuum brazing, the joints are linear and follow the coolant channel alongside to provide a pressure-resistant design.

We can FSW within a work area of 2500×700 mm, with overall part size as big as 3000x800mm.

FSW is cost-effective and high quality process, now becoming a standard in welding automotive parts for battery and inverter cooling.