Our manufacturing area for cooling units and assemblies has a total of 4 different production lines.

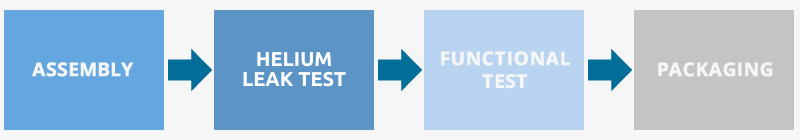

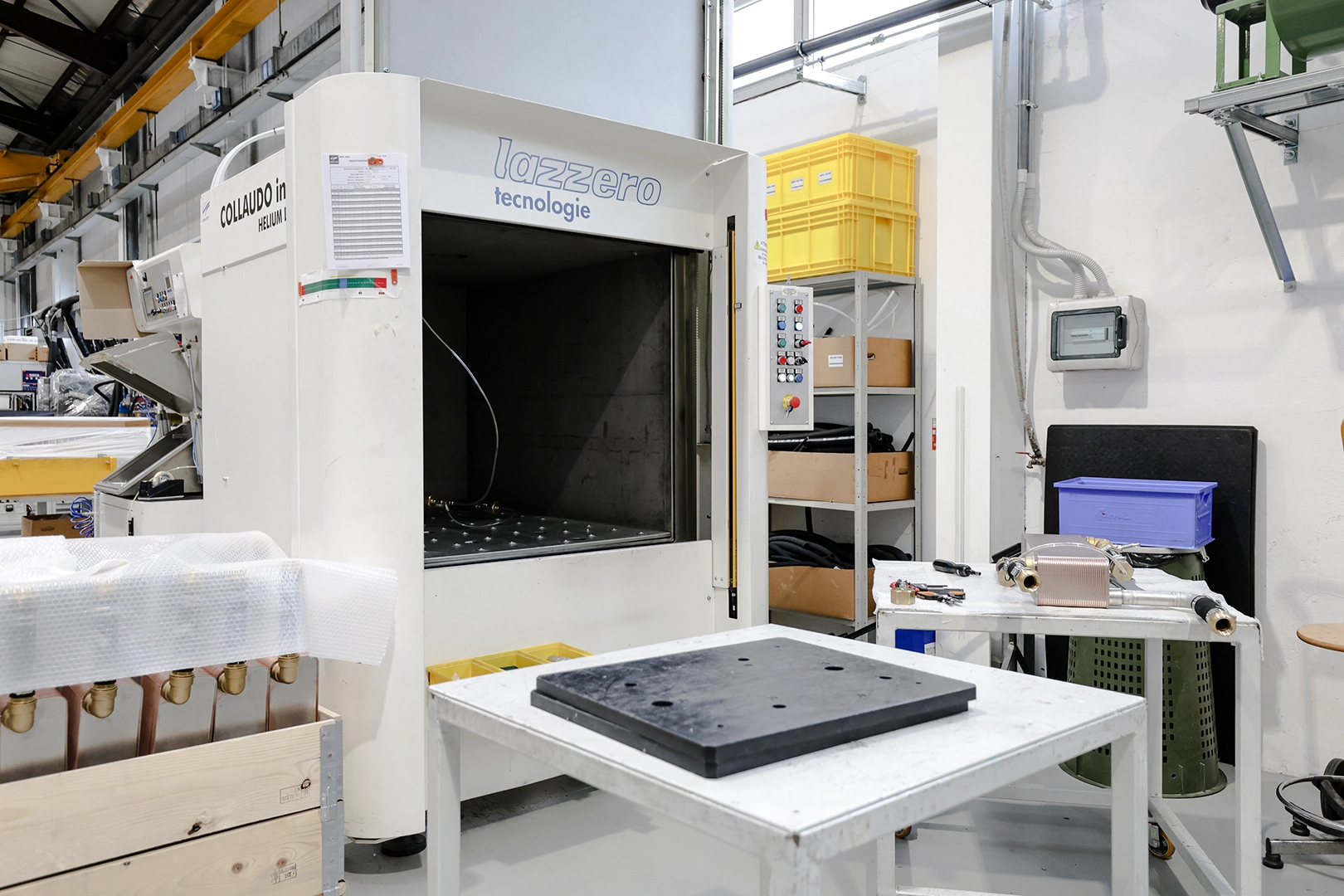

- Line A: Small assemblies with a maximum size of 500x500x500mm.

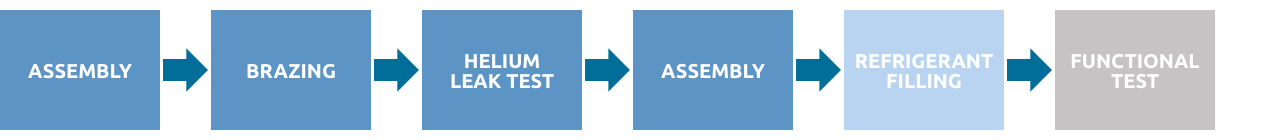

- Line B: Medium to Big size cooling systems line including brazing station for refrigerant circuits for chiller units.

Line A and B are based on flexible and modular organization, that means we extremely fast to reorganize them following the market and customer needs.

- Line C: Clean environment line. Cooling units assembled and tested in a 400 square meter ISO 8 clean room.