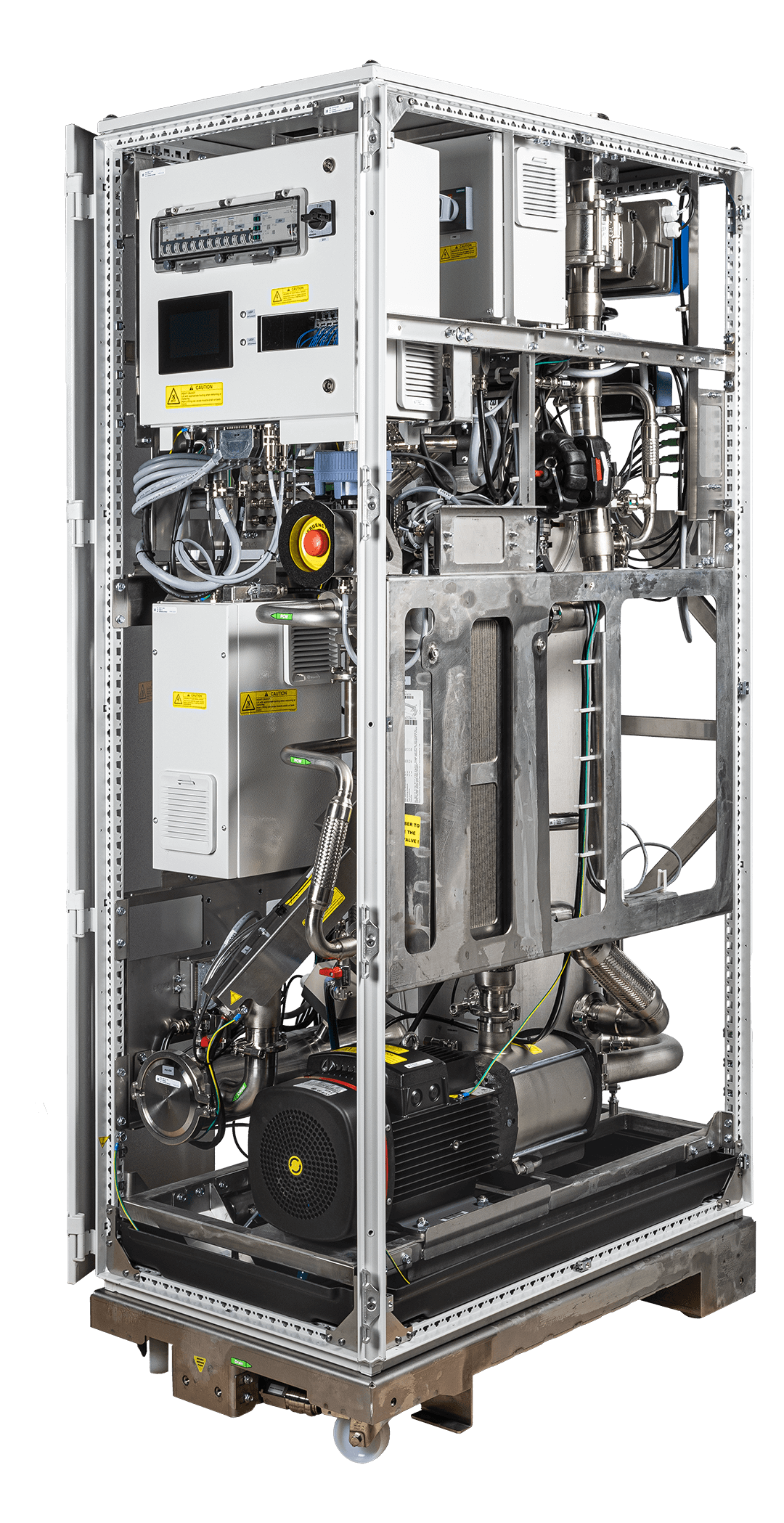

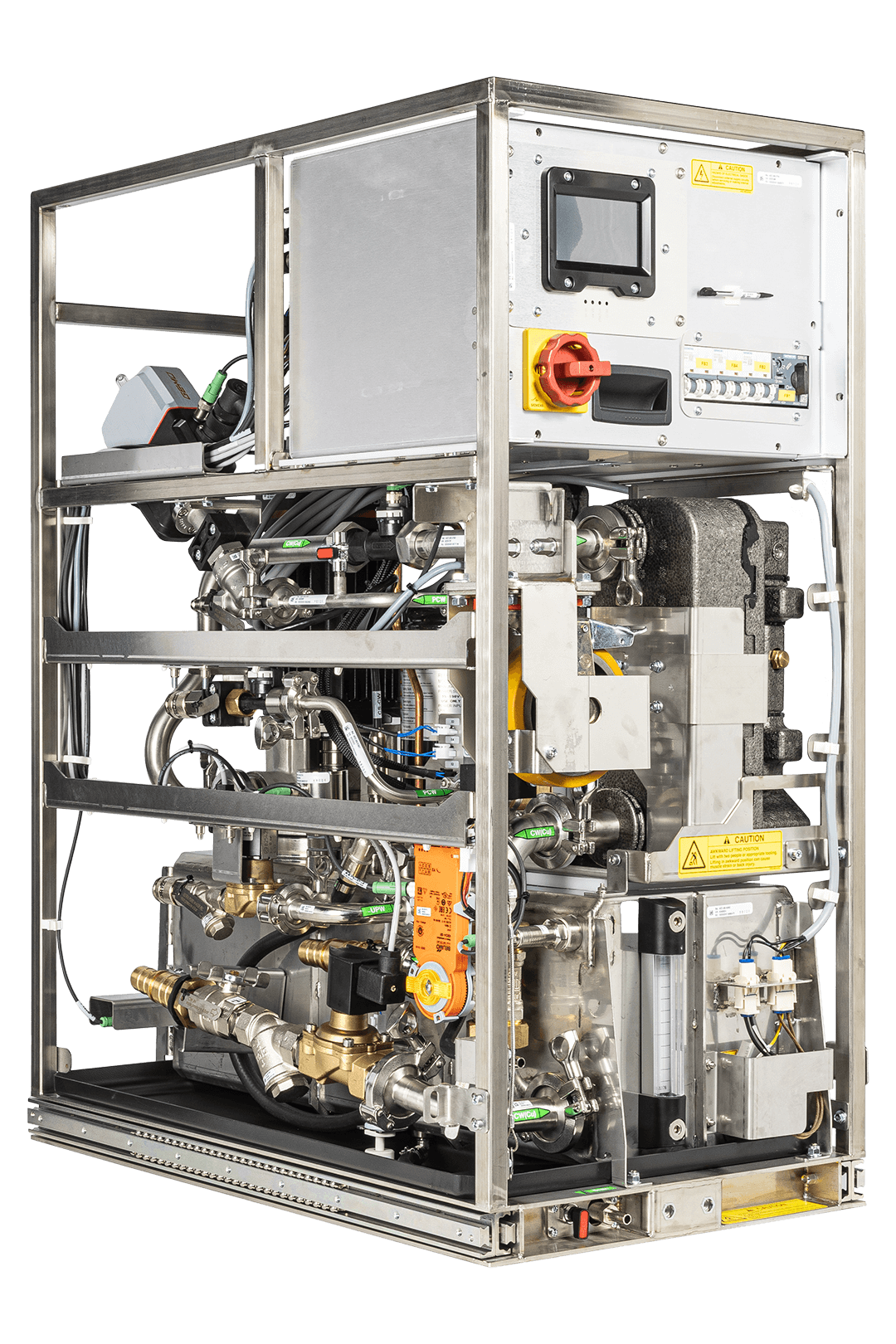

The Cooling Unit B.U. offers a wide range of customized cooling units. Every unit is the result of an engineering project which starts with the specification of the customer and ends with the qualification of the final prototype.

COOLTECH do not offer a catalogue of standard units. We have a strong know-how in the field of liquid cooling and every unit is designed to offer the best performances and reliability.

Anyhow thanks to our strong and consolidated supply chain we can offer a good price range with respect the features of the cooling system.

Our engineering team can develop from simple subassembly for OEMs to complete PLC controlled cooling solutions. Our cooling units are all conform to CE and, upon request, can be UL certified as well as other norms.

Our product topology consists in three different families of cooling units.